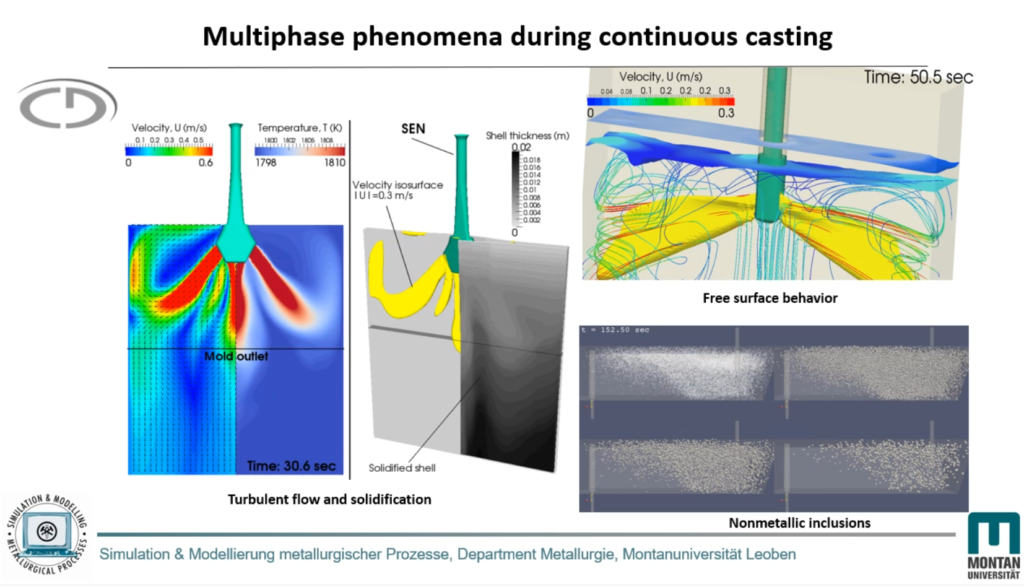

Continuous casting

The continuous casting (CC) of steel comprises complex multiphase phenomena, such as turbulent melt flow, solidification, free surface waving, motion of the nonmetallic inclusions and gas bubbles, etc.

The numerical models, aimed to track the course of the CC process, include coupling between liquid flow, growth of the solid shell, buildup of the mechanical stresses, etc. Sloshing of the meniscus due to the mold flow instabilities, clogging or misalignment submerged entry nozzle (SEN) are under investigation.

As an excellent experimental tool for the casting scenarios, the computational fluid dynamics (CFD) allows to study different flow control techniques, such as the electromagnetic braking (EMBr). Numerical modelling assists to disclose how does the mold and SEN flow alternate under the applied magnetic field; how the solidification profiles are affected; how the meniscus stability evolves under the EMBr.