Crystal growth

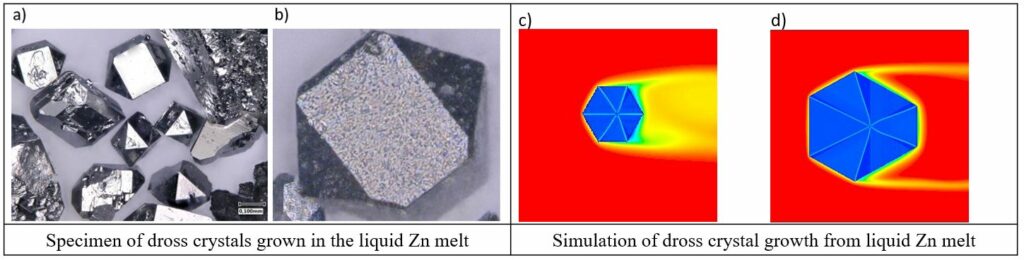

A front tracking interface model based on a cellular automaton approach was develop to tackle the problem of faceted growth under hydrodynamic condition. Interface kinetics, together with solute transport by diffusion and convection were fully considered. The propagation of kinks was expressively modelled by differentiating normal and lateral growth velocities at each facet and the positions of the corners are shifted according to the growth of adjacent faces. Hydrodynamic was computed with a two-phase (liquid-solid) model using a penalty method to model the presence of growing obstacles (crystals).

This model was applied to the growth of a floating Fe2Al5 crystal (also known as top dross particle) in a saturated Zn melt at constant temperature. In the galvanizing industry their occurrence is a problem and therefore it should be limited.

The crystal growth rate was found to be influenced by the intensity of the melt flow and by the direction of the flow with respect to the crystal orientation. The magnitude and the direction of flow modify the diffusion boundary layer, changing the conditions (temperature and concentration) at the facet interface, therefore the mass transfer and consequently the growth. We have shown that despite the isotropy of the interfacial kinetics, hydrodynamics was able to introduce an anisotropy in the crystal growth similar to the natural anisotropy in interfacial kinetics of the facets.

Built-up growth

The model was applied to the dross build-up growth (Fe2Al5 faceted crystals) occurring during the production of Zn coated (Galvanizing industry) on the bath hardware. In the galvanizing industry their occurrence is a problem and therefore it should be limited. The simulation cases reproduce the industrial conditions of the build-up growth on the stationary hardware and on the rotating bath hardware. Comparison was made between simulation results (up) and experimental observation of crystals shape (down).

The simulations show that the build-up growth is coupled with the flow hydrodynamics, through the modification of the concentration field in the liquid. Many eddies will transport liquid zinc with high concentration in Fe and Al to the close vicinity of the crystals. The growth rate increases with the increase of the strip velocity, respectively 30% faster for 2 m/s compared to 1m/s. A novel finding was the influence of the roughness on the crystal’s growth velocity; the peaks grow faster than the depressions. These results could explain why in industry the build-up growth is generally faster for higher steel strip velocity.

Publications

1) Stefan-Kharicha M., Kharicha A., Zaidat K., Reiss G., Eßl W., Goodwin F., Wu M., Ludwig A., Mugrauer C.: J. Crystal Groth. 541 (2020) DOI: 10.1016/j.jcrysgro.2020.125667

“Impact of hydrodynamics on growth and morphology of faceted crystals”

2) Stefan-Kharicha M., Kharicha A., Zaidat K., Reiss G., Eßl W., Goodwin F., Wu M., Ludwig A., Mugrauer C.: J. Crystal Groth. 584 (2022), “Hydrodynamically driven facet kinetics in crystal growth”, https://doi.org/10.1016/j.jcrysgro.2022.126557

3) Stefan-Kharicha M., Kharicha A., Zaidat K., Reiss G., Eßl W., Goodwin F., Wu M., Ludwig A., Mugrauer C.: Galvatech 2021 (online conference), Numerical simulation of build-up growth coupled with hydrodynamics