Electric arc furnace

The Electric Arc Furnace (EAF) uses an electric arc to melt various raw and scrap materials.The EAF system operates with either AC or DC electric currents. The heart of the EAF process is the electric arc, the high energy released by the arc renders the atmosphere into plasma in the arc column making it electrically conductive. The flow is driven strongly by the self-induced electromagnetic forces near the cathode spot. The plasma column generates an enormous amount of heat (Joule heating) capable of melting the solid scrap/ore into liquid metal.

Numerical simulations aim to predict the behavior of the electric arc and further extend the understanding the driving mechanisms behind it. The numerical model includes the flow dynamics, thermal fields, magnetohydrodynamics fields and multiphase aspect. The model is capable of predicting the detailed behavior of the single-phase compressible arc dynamics, in addition to arc impingement on liquid metal in two phase flow simulation. The model is also capable of predicting the electro vortex flow inside liquid metal.

The overall research tackles to achieve better understanding of the operation and dynamics of the electric arc furnace. The developed model of the full furnace scale and detailed model of the arc will further extend our knowledge for areas where experimental data is not possible due to extreme conditions. This research will help the industry enhance their understanding of the behavior of the electric arc and how to have better control on its dynamics. This can lead to minimize the evaporation rate of the graphite electrodes and extend its lifespan. Moreover, better understand of the arc impingement and flow inside slag and liquid metal will enable to enhance and optimize the melting process and prevent overheating events and excessive wear of refractories walls. The knowledge out of this research can be extended to different electric furnace operation with various operating conditions. Additionally, the model will be used for different furnace atmospheres for instance: hydrogen and argon which are more environmentally friendly and awaits further enhancement and optimization.

High intensity arc 40 kA arc with a fixed current density at the cathode spot is simulated. The simulation is able to predict the detailed behaviour of the arc dynamics and the aerodynamic wings generated by instabilities emerging at the cathode spot. The white contour shows the isothermal temperature of 10 000 K (arc region). The left top shows the temperature contours and right top shows velocity contours. The graph shows the voltage drop across the arc domain.

The simulation shows the arc impingement on liquid metal with a current of 30 kA and gap distance of 25 cm. The streamlines on the left side shows the current path inside the plasma.

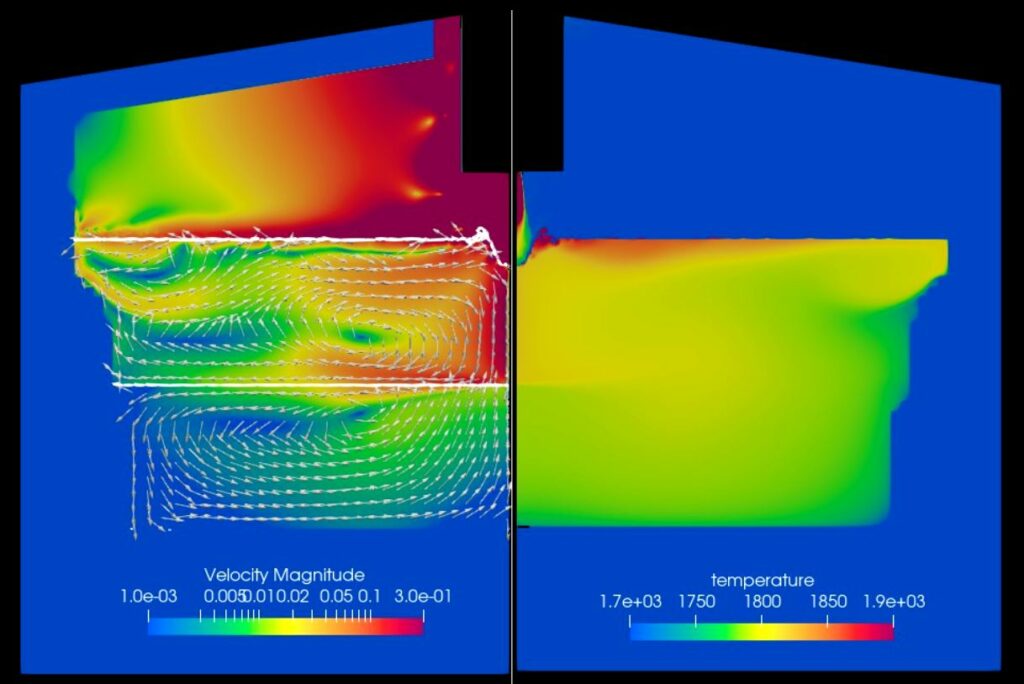

A full dimensional 3D axisymmetric simulation has been carried out for a DC EAF furnace including the arc, slag and liquid metal inside liquid slag and liquid metal. The geometry also accounts for the refractories and furnace roof. The simulation predicts the arc impingement on slag surface and the flow inside the melted slag and liquid metal

Publications

1)

2)