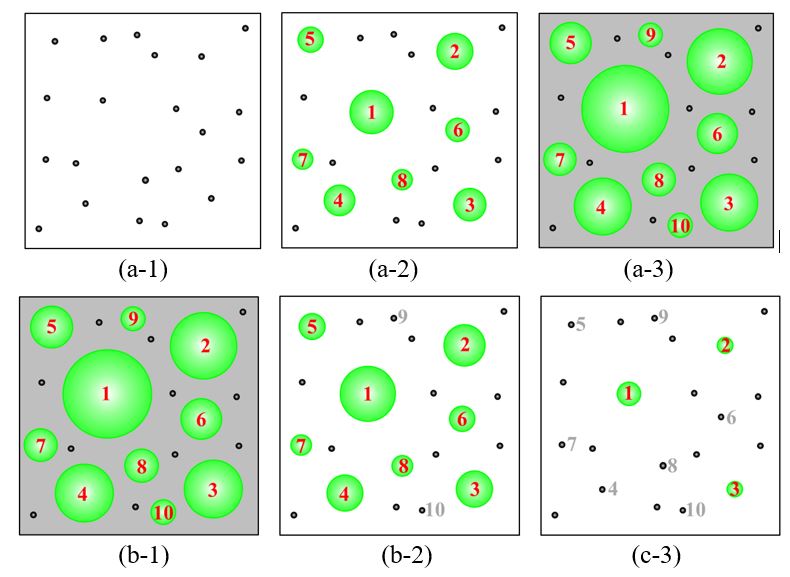

Melting or re-melting accompanies solidification in many technical castings. For example, during ingot casting, some crystal fragments or equiaxed grains can enter the superheated region and re-melt, while solidification continues in other regions. This simultaneous solidification/melting process in the casting domain acts as an important species/energy transport mechanism between the liquid melt and solid grains, which impacts the structural/compositional homogeneity of the castings. The re-melting is typically understood as a reduction in the equiaxed grain size, but it can also lead to the destruction (disappearance) of equiaxed grains. Existing process-based models cannot treat the solidification/melting by considering both crystal nucleation and destruction properly. Therefore, a new model is proposed based on a two-phase volume-average approach. In this model, nucleation of equiaxed grains occurs when inoculants (free growth sites) are activated by undercooling, while destruction of equiaxed grains occurs only when the equiaxed grains are completely re-melted by superheating. The mass, momentum, species, and enthalpy conservation equations are solved for the solidification/melting. The transports of the number densities of equiaxed grains and inoculants are calculated separately. A test casting (Al–7 wt.% Si) is calculated to illustrate the modeling features. This study improves understanding of crystal melting and grain destruction as well as their impact on the as-solidified structure.

Schematic of (a) the nucleation and grain growth and (b) the re-melting and grain destruction processes. The black dots denote the inoculants, the green spheres indicate the equiaxed grains, and the grey background indicates the eutectic phase. All grains are numbered from 1 to 10.